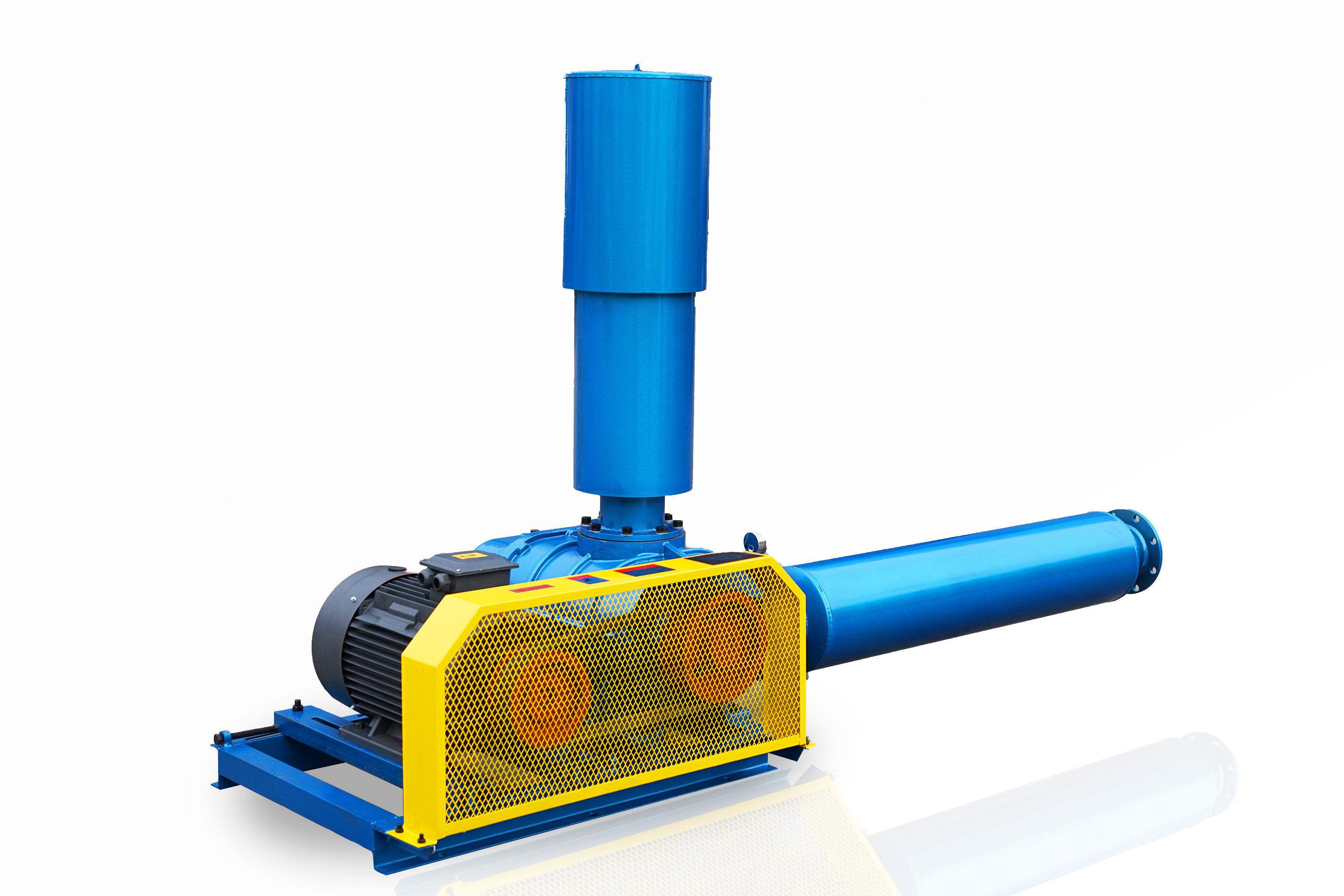

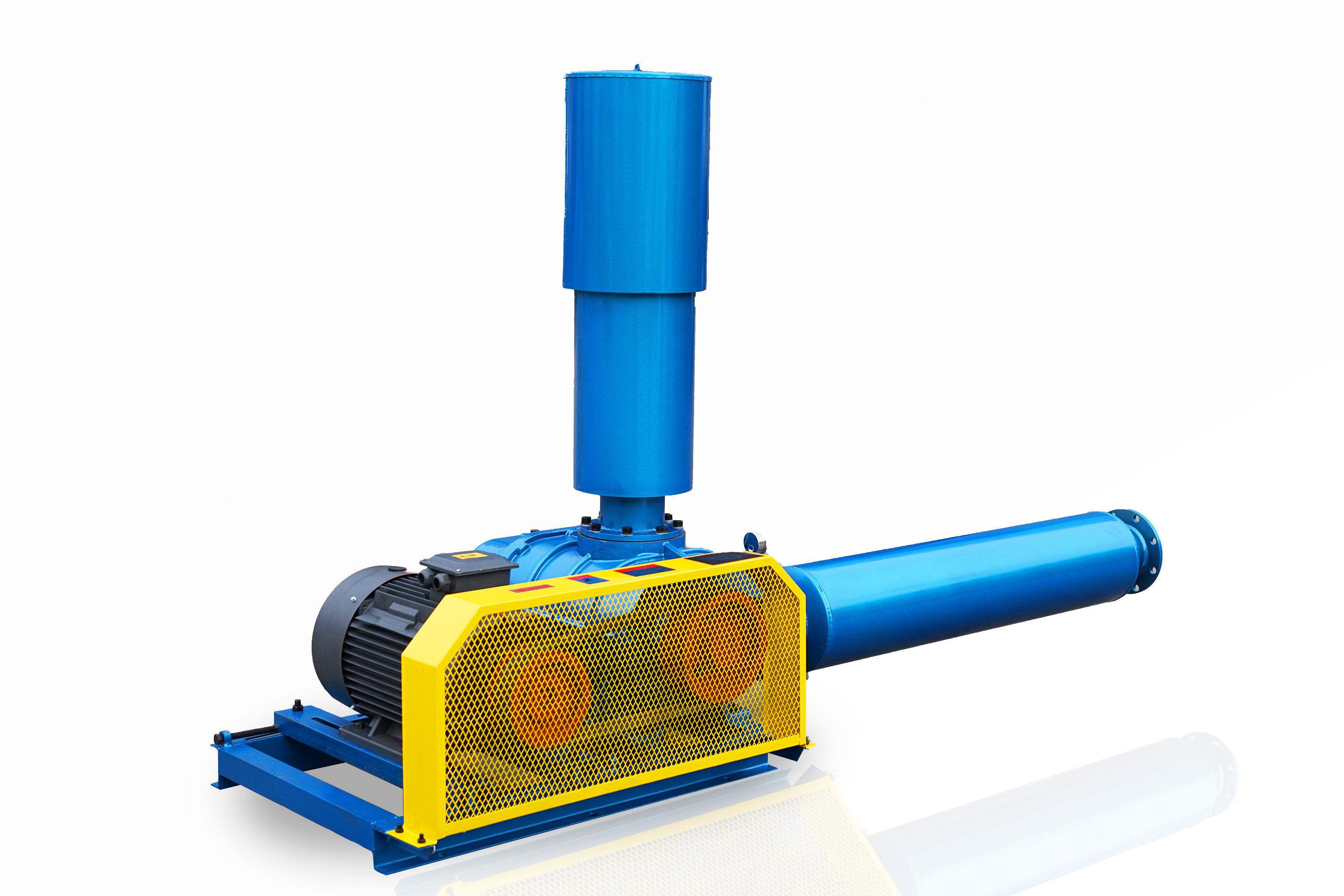

在什么情况下不能使用罗茨风机:

Under what circumstances can roots blower not be used:

1、机器故障

1. Machine fault

这一点其实不用说,因为你知道,设备是存在故障确实不能使用,但会有人感觉有轻微的故障,但可以继续运转,不能那样想。这样会损坏设备,得不偿失。所以要知道故障的时候要尽快修理以减少开支。

In fact, there is no need to say this, because you know that the equipment is faulty and can not be used. However, some people will feel that there is a slight fault, but they can continue to operate. They can't think that way. This will damage the equipment and will not pay off. Therefore, we should know that when the fault occurs, we should repair it as soon as possible to reduce expenses.

2.进气温度超过40度。

2. the air inlet temperature exceeds 40 ℃.

一般来说,铸铁罗茨风机入口温度超过40。就会出现问题,所以入口温度超过40时,运行时,设备停止工作。

Generally speaking, the inlet temperature of cast iron roots blower exceeds 40. There will be problems, so when the inlet temperature exceeds 40, the equipment will stop working during operation.

3.运输的气体是有毒的。

3. the gas transported is toxic.

有毒气体一般不用罗茨风机运输,即使用特殊材料密封,风险也比较大,不要运输毒气。

Toxic gas is generally not transported by roots blower, that is, it is sealed with special materials, and the risk is relatively high. Do not transport toxic gas.

4.运输气体具有可燃性和爆炸性。

4. the gas transported is flammable and explosive.

运输气体易燃易爆,需要对鼓风机进行特殊处理。没有经过特别处理的风机禁止运输这种气体。

The gas transported is flammable and explosive, so the blower needs special treatment. It is forbidden to transport this kind of gas by fans without special treatment.

5.环境中有很多灰尘

5. there is a lot of dust in the environment

如果设备在灰尘多的环境中使用,会有很大容量的微粒灰尘进入风扇,间隔太小,引起风风机损坏。罗茨风机的使用条件需要根据实际情况,不允许使用非标准鼓风机,防止鼓风机故障。

If the equipment is used in a dusty environment, a large amount of particulate dust will enter the fan at a too small interval, causing damage to the fan. The use conditions of Roots blower shall be based on the actual situation. Non standard blower is not allowed to be used to prevent blower failure.

如何正确关闭罗茨风机:

How to shut down roots blower correctly:

罗茨风机要严加注意,以便充分利用特性了解应用,实际操作方法,立即填满离心风机润滑脂,及时清洁管道和过滤器,显示器仪表板的主要参数,及时异常处理,请检查罗茨鼓风机系统预备器,然后做好准备工作。

Pay close attention to roots blower, so as to make full use of the characteristics to understand the application and the actual operation methods, fill the centrifugal blower grease immediately, clean the pipes and remove the filter in time, display the main parameters of the instrument panel, and handle the abnormalities in time. Please check the roots blower system preparer, and then make preparations.

检查器预备器的各阀门开关是否到位,确保罗茨风机出口阀门完全关闭,入口阀门完全打开。正常检查后,根据操作规定打开罗茨风机预备器。同时,罗茨风机的备用风机打开和正在用鼓风机停下来。如果备用风机正常工作。慢慢关掉机器出口,打开备用风机电路。同时逐渐关闭风机出口阀,使出口压力比原出口压力稍大。停止鼓风机出口工作压力。在执行上述任务的同时,在使用风机出口阀时逐渐关闭,用鼓风机出口阀门,使其出口压力略大于原来的出口孔施加压力。在这整个过程中,要保持风及压力出口,确保压力平衡,可能的系统压力稳定性。逐渐使用罗茨风机副线阀门和出口阀门。完全关闭,备用罗茨风机的副线阀门和出口阀门完全打开,到这时为止,机器停止运行,完成罗茨风机切换。

Check whether the valve switches of the preparer are in place, and ensure that the outlet valve of Roots blower is fully closed and the inlet valve is fully opened. After the normal inspection, open the roots blower preparator according to the operating regulations. At the same time, the standby blower of Roots blower is on and the blower is stopping. If the standby fan works normally. Slowly turn off the machine outlet and turn on the standby fan circuit. At the same time, gradually close the fan outlet valve to make the outlet pressure slightly higher than the original outlet pressure. Stop the blower outlet working pressure. While performing the above tasks, gradually close the fan outlet valve when using it, and use the blower outlet valve to make its outlet pressure slightly greater than the pressure applied by the original outlet hole. During the whole process, the air and pressure outlet shall be maintained to ensure pressure balance and possible system pressure stability. Gradually use the auxiliary line valve and outlet valve of Roots blower. Fully close, and the auxiliary line valve and outlet valve of the standby roots blower are fully opened. Until then, the machine stops running and the switching of Roots blower is completed.

1、手动齿轮上的罗茨鼓风机控制柜控制手柄,关闭罗茨鼓风机吸入口阀门和真空系统隔板。

1. The control handle of Roots blower control cabinet on the manual gear closes the valve at the suction inlet of Roots blower and the diaphragm of vacuum system.

2、主机、中间泵前置水冲洗泵顺序,阶段性停止泵,不要误以为停机顺序,以免损坏机器。

2. The main engine and intermediate pump shall be flushed with pre water, and the pump shall be stopped periodically. Do not mistake the shutdown sequence to avoid damaging the machine.

3、停止前水冲洗泵时,先打开水冲洗泵缓冲槽排放脏阀门,后泵关闭。

3. When stopping the front water flushing pump, open the dirty discharge valve in the buffer tank of the water flushing pump first, and then close the pump.

The above is Shandong electric sunshade http://www.qdjhpc.com/ Thank you for checking the information of our company in your busy schedule. If you want to know more, you are welcome to call us for consultation