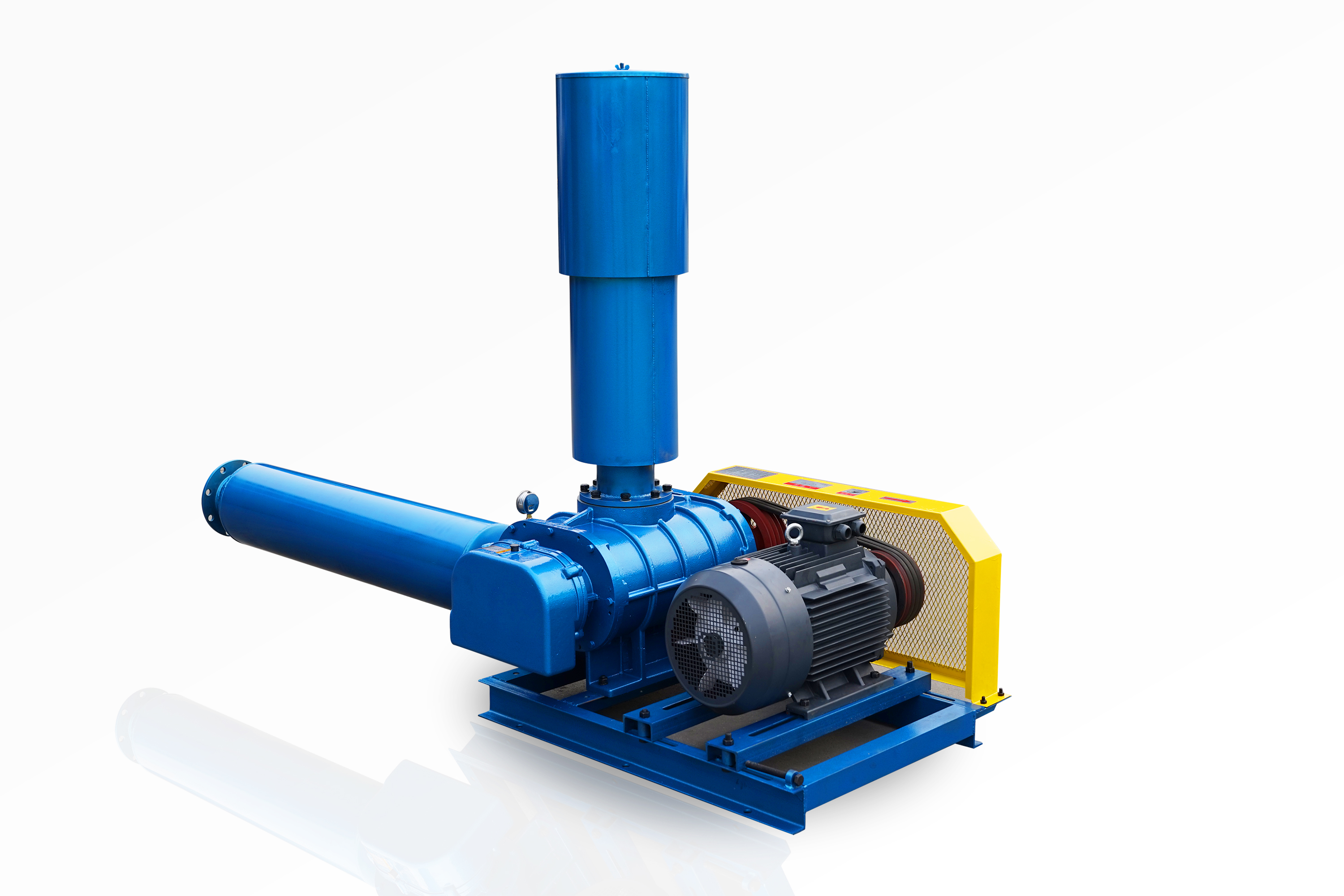

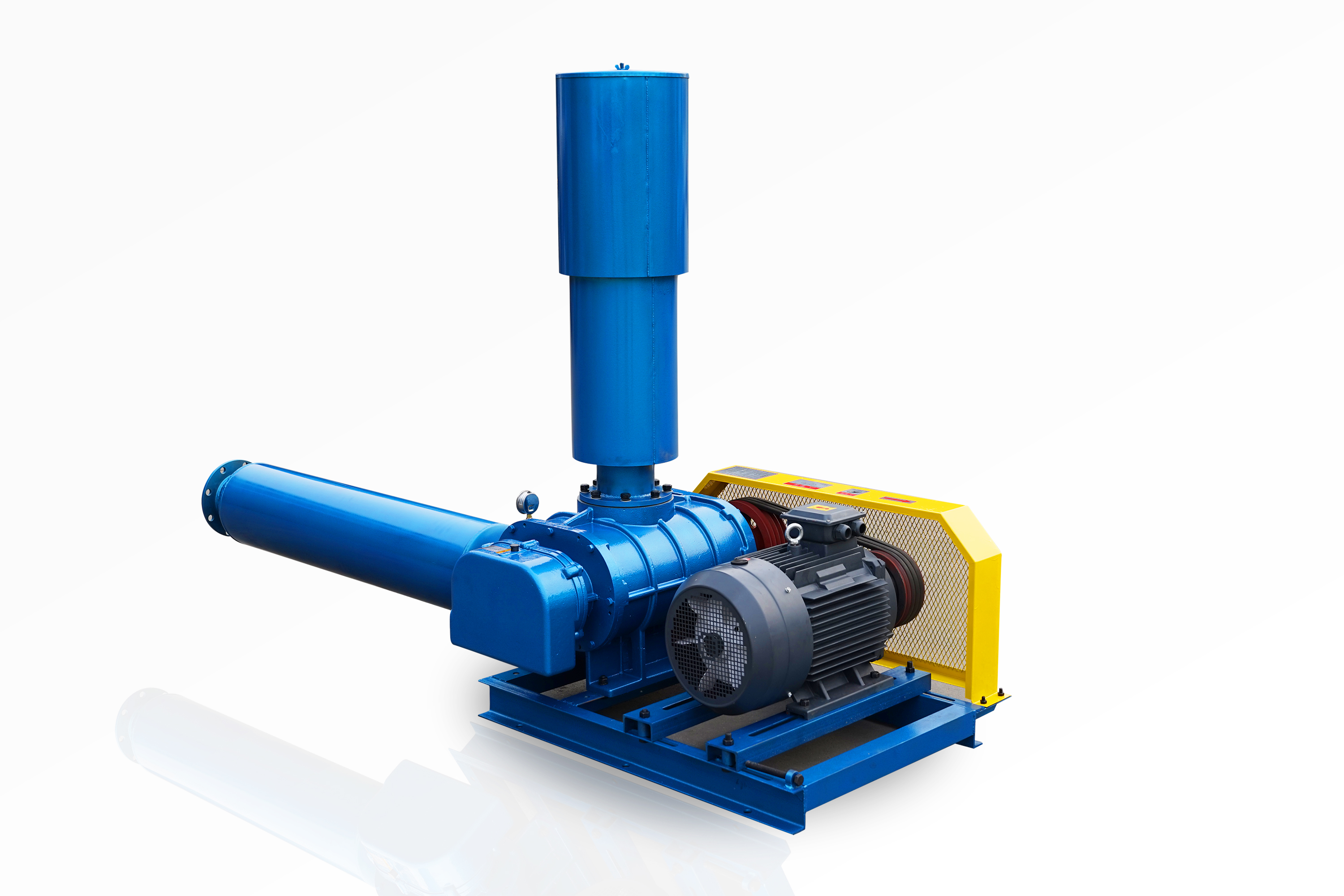

星型卸料器旋转供料器性能优势及特点:

Performance advantages and characteristics of star unloader rotary feeder:

1、本产品加工精度高,具有锁气功能,可用于粉碎、分级系统的粉料定量供料器,又可作为分离、收尘等系统的卸料器,或用于压送式、吸送式气力输送系统。

1. This product has high processing accuracy and air lock function. It can be used as the powder quantitative feeder of the pulverization and classification system, as the discharger of the separation and dust collection systems, or for the pressure feeding and suction feeding pneumatic conveying systems.

2、带有压力平衡装置,可用在正压、负压输送系统。

2. With pressure balancing device, it can be used in positive pressure and negative pressure conveying systems.

3、可采用铸铁、铸钢、不锈钢、钛钢等多种材质,法兰口可为方形或圆形等多种结构形式,满足用户不同需求。

3. Cast iron, cast steel, stainless steel, titanium steel and other materials can be used. The flange can be square or round and other structural forms to meet the different needs of users.

星型卸料器工作原理:卸料器是由带有数个叶片的转子在圆筒形机壳内旋转,从上部料斗落入的物料,充塞在叶片间的空格内,随叶片的旋转而卸出。星型卸料器工作时,粉尘靠自身重力落下,充满上面和侧面的星形叶片空格内。叶片转子由电动机通过减速机转动轴带动,叶轮转到下部粉尘靠自重卸下。这种卸尘器一般都安装在除尘器灰斗下部,为保证连接处的严密不漏风,在回转卸料器的上部应经常保持(储存)一定高度的粉尘。因为叶轮转动时,卸完粉尘后叶轮转上的那一面经常是没有粉尘的,所以容易使空气漏入。为了保证不漏气应保持一定高度的灰尘柱,使其不致卸空,在灰斗内装设料位信号设施,并与卸尘阀的电动机建立连锁。

Working principle of star discharger: the discharger is a rotor with several blades rotating in the cylindrical shell. The materials falling from the upper hopper are filled in the space between the blades and discharged with the rotation of the blades. When the star unloader works, the dust falls down by its own gravity and fills the space of the star blade on the top and side. The blade rotor is driven by the motor through the rotating shaft of the reducer, and the impeller rotates to the lower part, and the dust is unloaded by its own weight. This type of dust remover is generally installed at the lower part of the ash hopper of the dust remover. In order to ensure the tightness of the connection and no air leakage, a certain height of dust should be kept (stored) at the upper part of the rotary unloader. When the impeller rotates, the side on which the impeller rotates after the dust is discharged is often free of dust, so it is easy to leak air. In order to ensure that there is no air leakage, a certain height of dust column shall be maintained so that it will not be emptied. Material level signal facilities shall be installed in the ash hopper and interlocked with the motor of the dust discharge valve.

星型卸料器又称为电动卸灰阀、关风器,刚性叶轮给料机等,是除尘设备,输送、排灰、关风和其它设备给料的主要装置,适用于各种粉状物料、颗粒物料的输送。它由电机、齿差行星减速器(X)或针纶摆线减速机(Z)与转龙式卸料器等三大部分组成。一般分为两大系列,60多种规格。即A型和B型两大系列,进出口法兰方形的为A型,圆形的为B型。星型卸料器阀体和叶轮可用钢板焊制,也可铸造。采用铸造方式叶片耐磨性好,叶片与传动轴钢型连接结构紧凑工作可靠,可以做成铸铁、铸钢、不锈钢等材质的。

Star type discharger is also known as electric ash discharge valve, air shutoff, rigid impeller feeder, etc. it is the main device for dust removal equipment, conveying, ash discharge, air shutoff and other equipment feeding, and is suitable for conveying various powdery materials and granular materials. It is composed of three parts: motor, tooth difference planetary reducer (x) or needle fiber cycloid reducer (z) and rotary dragon unloader. It is generally divided into two series and more than 60 specifications. I.e. type A and type B series. The square inlet and outlet flanges are type A and the round ones are type B. The valve body and impeller of star unloader can be welded with steel plate or cast. The cast blade has good wear resistance. The blade and the transmission shaft are connected in a compact structure and work reliably. It can be made of cast iron, cast steel, stainless steel and other materials.

The above is the detailed introduction of Kejiang high seal rotary feeder. I hope it will help you. If you have any questions, please contact us. We will provide you with services with a professional attitude http://www.sddyfd.com/