气力输送系统分类有哪些?

What are the classifications of pneumatic conveying systems?

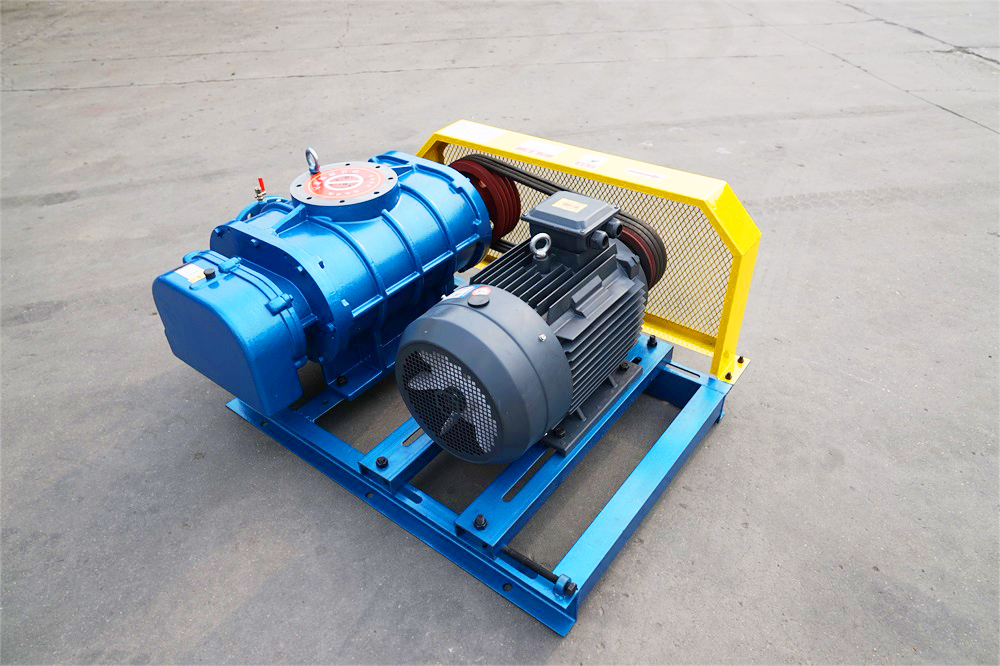

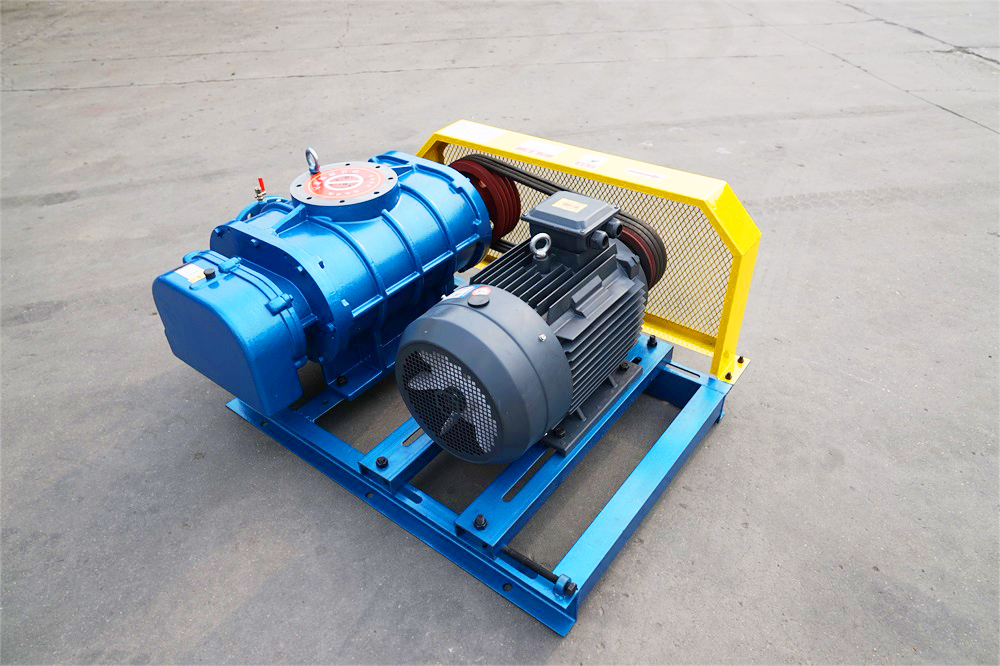

气力输送设备一般由受料器(如喉管、吸嘴、发送器等)、输送管、风管、分离器(常用的有容积式和旋风式两种)、锁气器(常用的有翻板式和回转式两种,既可作为喂料器,又可作为卸料器)、除尘器和风机(如离心式风机、鼓风机、水环真空泵、空压机等)等设备和部件组成。受料器的作用是进人物料,造成合适的料气比,使物料启动、加速。分离器的作用是将物料与空气分离,并对物料进行分选。锁气器的作用是均匀供料或卸料,同时阻止空气漏人。风机的作用是为系统提供动力。真空吸送系统常用高压离心风机或水环真空泵;而压送系统则需用罗茨鼓风机或空压机。

Pneumatic conveying equipment is generally composed of feeder (such as throat, suction nozzle, transmitter, etc.), conveying pipe, air pipe, separator (commonly used are volumetric and cyclone), air lock (commonly used are flap and rotary, which can be used as both feeder and discharger), dust collector and fan (such as centrifugal fan, blower, water ring vacuum pump, air compressor, etc.). The function of the feeder is to feed the material to create an appropriate material gas ratio, so that the material can be started and accelerated. The function of separator is to separate materials from air and sort materials. The function of air lock is to evenly feed or discharge materials and prevent air leakage at the same time. The function of the fan is to provide power for the system. High pressure centrifugal fan or water ring vacuum pump are commonly used in vacuum suction system; The pressure delivery system requires roots blower or air compressor.

1.吸送式气力输送系统

1. suction pneumatic conveying system

气源设备在系统的末端。当风机运转后,整个系统形成负压,管道内外产生压差,空气被吸入输料管道。物料也从吸嘴被空气带入管道,通过管道进入分离收集器,然后物料通过旋转供料器进入储料罐,而空气则通过收集器中的过滤设备从风机中排除

The air supply equipment is at the end of the system. When the fan operates, the whole system forms a negative pressure, resulting in a pressure difference inside and outside the pipeline, and the air is sucked into the material transmission pipeline. The material is also brought into the pipe by air from the suction nozzle, and enters the separation collector through the pipe. Then the material enters the storage tank through the rotary feeder, and the air is discharged from the fan through the filter equipment in the collector

2.压送式气力输送系统

2. pressure pneumatic conveying system

气源在输送设备的前端,因此,物料进入输送罐使用有密封压力的供料装置。一般在低压时,使用的是旋转供料器;高压时,使用流化罐。物料通过阀门进入输送罐,再通过蝶阀进入流化罐,通过量位仪或者称量秤控制其进料量,当达到要求后,蝶阀关闭,通入空气使物料流态化,开启流态化下端的阀门,通过空气将物料和空气的混合物压入管道。

The air source is at the front end of the conveying equipment. Therefore, the material entering the conveying tank uses a feeding device with sealing pressure. Generally, the rotary feeder is used at low pressure; At high pressure, use fluidizing tank. The materials enter the conveying tank through the valve, and then enter the fluidization tank through the butterfly valve. The feeding amount is controlled by the level meter or weighing scale. When the requirements are met, the butterfly valve is closed, air is introduced to fluidize the materials, the valve at the lower end of the fluidization is opened, and the mixture of materials and air is pressed into the pipeline through the air.

The wonderful content of this article is provided by the knowledge of Guangxi pneumatic conveying scheme design. There are many wonderful content on this website. You can click to enter more content http://www.sddyfd.com/ We have special customer service to answer your questions