粉粒物料气力输送原理,就是将粉粒物料利用空气将其混合,形成一种特定浓度的气固混合物,在压差作用下进入输送管道,将气固混合物沿管道向前推进直达受料仓内,固体物料在重力下落入受料仓内,空气经仓顶除尘器过滤后排入大气,实现气固分离,达到粉粒物料远距离输送目的。

The pneumatic conveying principle of powder materials is that the powder materials are mixed with air to form a specific concentration of gas-solid mixture, which enters the conveying pipeline under the action of differential pressure, and the gas-solid mixture is pushed forward along the pipeline to the receiving bin. The solid materials fall into the receiving bin under gravity, and the air is filtered by the dust collector on the top of the bin and discharged into the atmosphere to realize gas-solid separation and achieve the purpose of long-distance conveying of powder materials.

粉粒物料气力输送系统,工艺要求各有不同,是按实际工况通过量身定制而设计的智能化粉体输送装备。主要分为;高正压、低正压、真空负压。

The pneumatic conveying system for powder materials has different process requirements. It is an intelligent powder conveying equipment designed according to the actual working conditions. Mainly divided into; High positive pressure, low positive pressure, vacuum negative pressure.

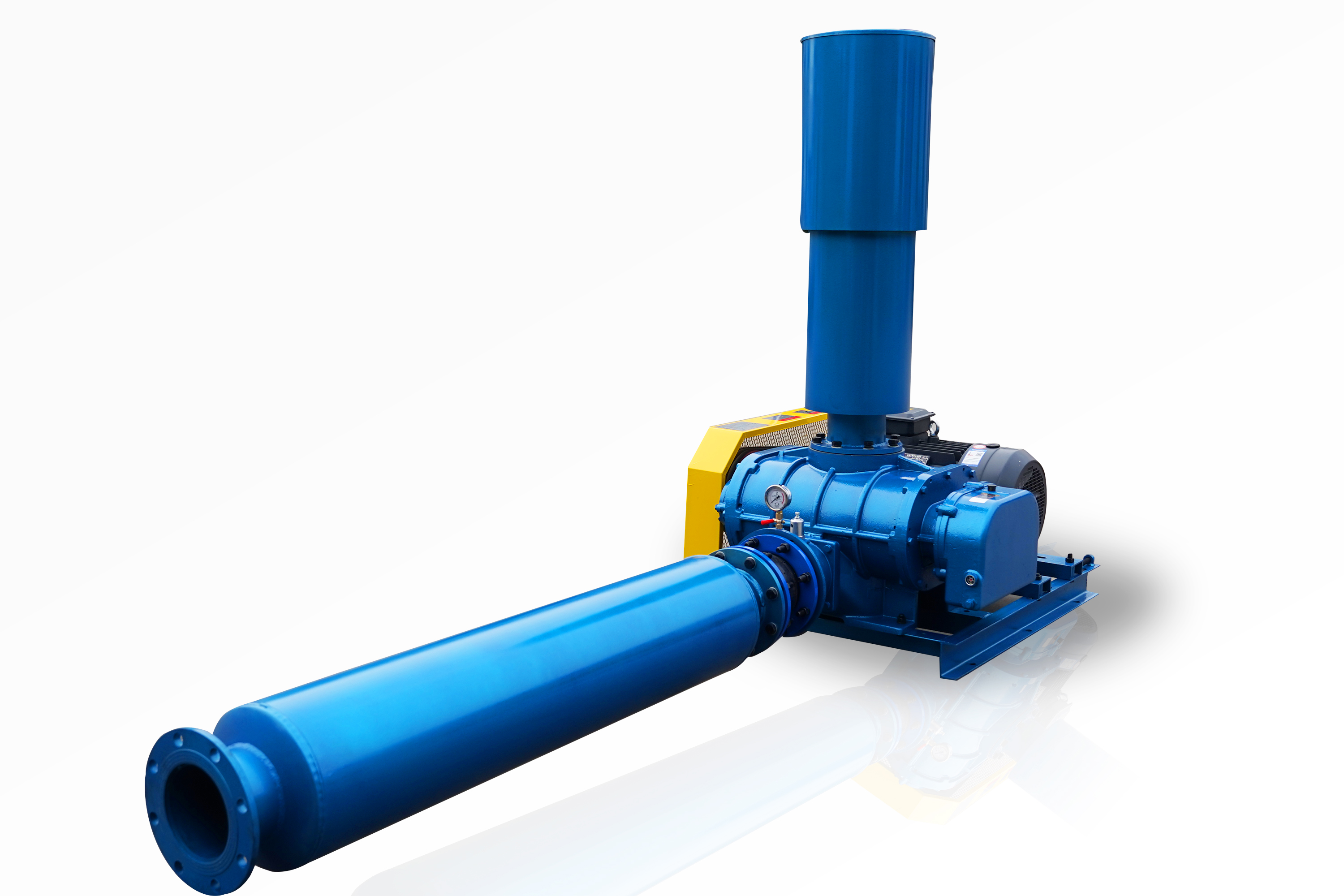

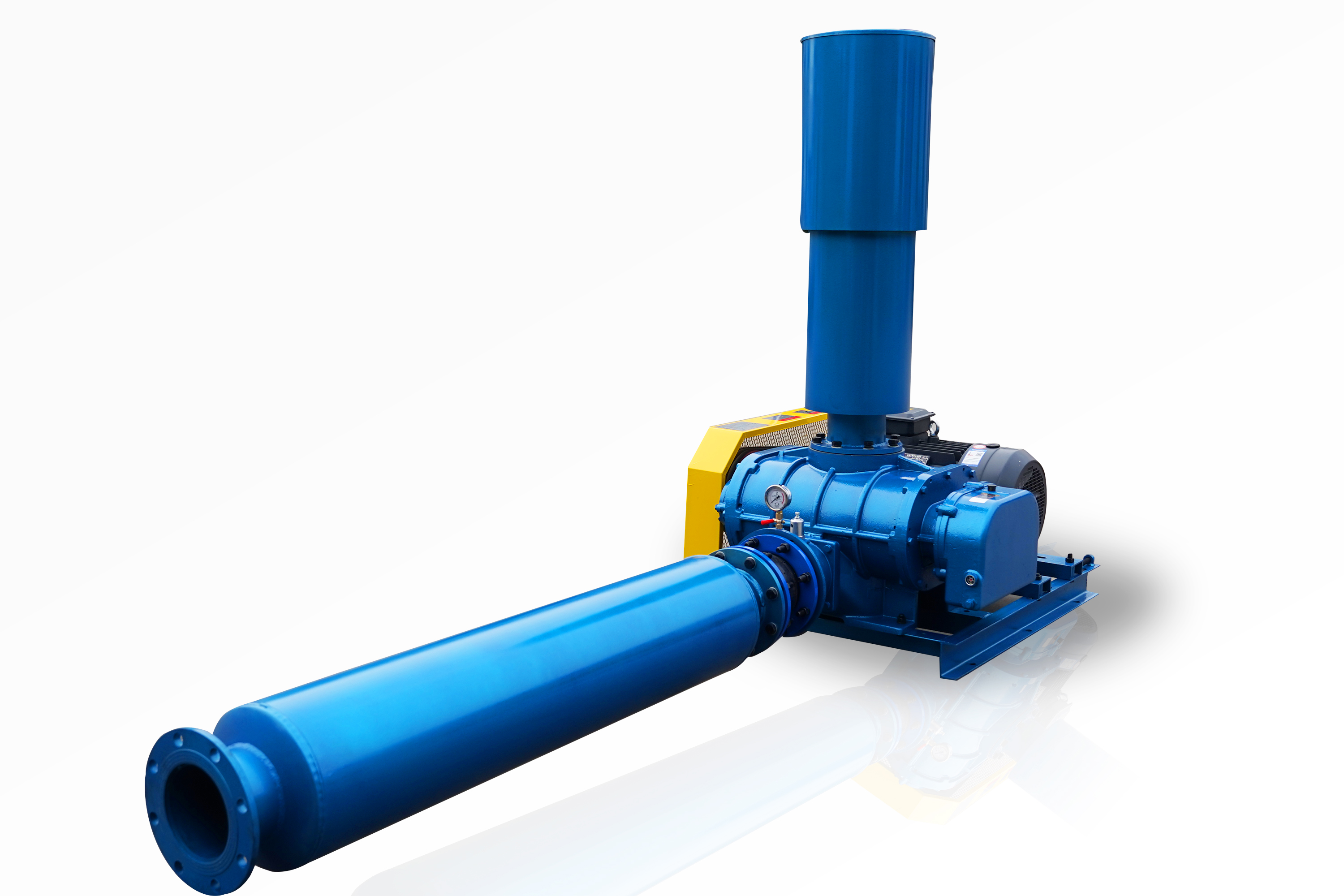

高正压输送设备有;上引式粉体输送泵、中引式粉体输送泵、下引式粉体输送泵、浓相粉体输送泵、灰碴输送泵、粉体计量输送泵、高炉煤粉喷吹泵、恒量可调粉体输送泵等。

High positive pressure conveying equipment:; Up lead powder conveying pump, middle lead powder conveying pump, down lead powder conveying pump, dense phase powder conveying pump, ash slag conveying pump, powder metering conveying pump, blast furnace pulverized coal injection pump, constant adjustable powder conveying pump, etc.

低正压输送设备有;低压连续输送泵、低压螺旋输送泵、窑炉粉体喷吹泵等。

Low positive pressure conveying equipment:; Low pressure continuous conveying pump, low pressure spiral conveying pump, kiln powder injection pump, etc.

负压输送设备有;真空负压粉体输送泵,粉体真空负压卸船机,真空负压吸尘等。

Negative pressure conveying equipment:; Vacuum negative pressure powder conveying pump, powder vacuum negative pressure ship unloader, vacuum negative pressure dust collection, etc.

粉粒物料输送设计原则,根据物料特性(比如:物料堆比重、细度、莫氏硬度、含水率、安息角、温度)等系列参数,物料输送量、输送距离、气固比、管内流速、管道转向方式、弯头数量、输送高度、受料仓形式,上下游工艺,智能化控制等相关要求而设计的。

The design principle of powder material conveying is designed according to a series of parameters such as material characteristics (such as material pile specific gravity, fineness, Mohs hardness, moisture content, rest angle and temperature), material conveying capacity, conveying distance, gas-solid ratio, flow rate in the pipe, pipeline steering mode, number of elbows, conveying height, silo form, upstream and downstream process, intelligent control and other relevant requirements.

物料高浓度输送,固比高,气比低,耗气量相应降低,则空压机能耗也相应降低,物料低浓度输送,固比较低,气比较高,耗气量相应增加,则空压机能耗也相应增加。在粉体气力输送系统设计中,须综合物料特性、输送距离、弯头数量、输送高度等因数,适当提高输送浓度,使系统更。在输送距离较远,弯头较多,垂直输送较高的工况中,不建议将输送浓度设计过高,容易产生堵管现象。

When the material is transported with high concentration, the solid ratio is high, the gas ratio is low, and the gas consumption is reduced accordingly, the energy consumption of the air compressor is also reduced accordingly. When the material is transported with low concentration, the solid ratio is low, the gas ratio is high, and the gas consumption is increased accordingly, the energy consumption of the air compressor is also increased accordingly. In the design of powder pneumatic conveying system, the factors such as material characteristics, conveying distance, number of elbows and conveying height must be integrated to appropriately improve the conveying concentration and make the system more energy-saving. Under the conditions of long conveying distance, more elbows and high vertical conveying, it is not recommended to design the conveying concentration too high, which is easy to cause pipe blockage.

掌握气力输送系统核心技术也是达到物料浓相输送的关键,从目前看,有外旁路式,内套管式,气刀式等,输送工况不同则技术方案不同。

Mastering the core technology of pneumatic conveying system is also the key to achieve dense phase energy-saving conveying of materials. At present, there are external bypass type, internal casing type, air knife type, etc. the technical schemes are different under different conveying conditions.

The above is the design scheme of powder conveying in Yunnan http://www.sddyfd.com/ Thank you for checking the information of our company in your busy schedule. If you want to know more, you are welcome to inquire!