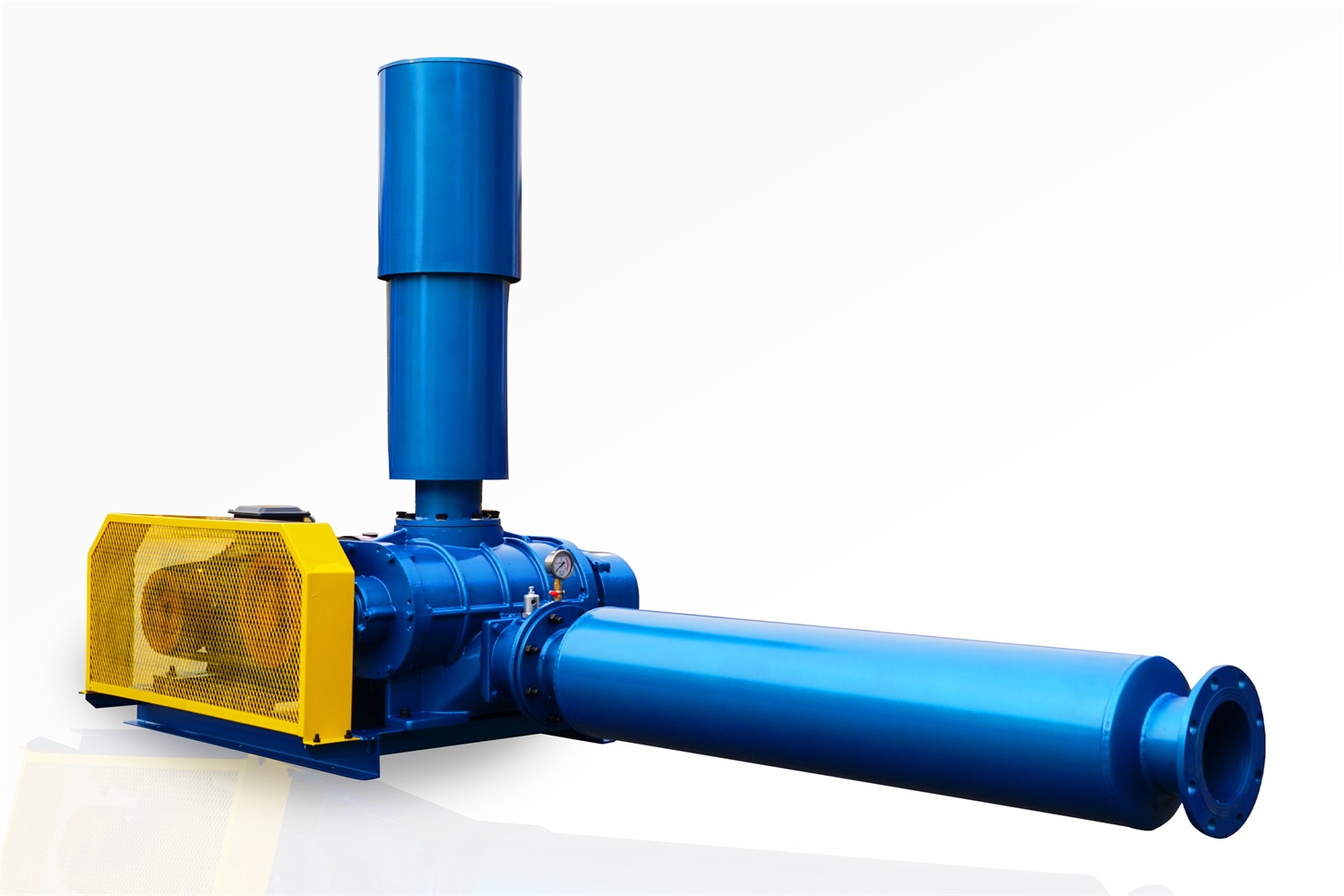

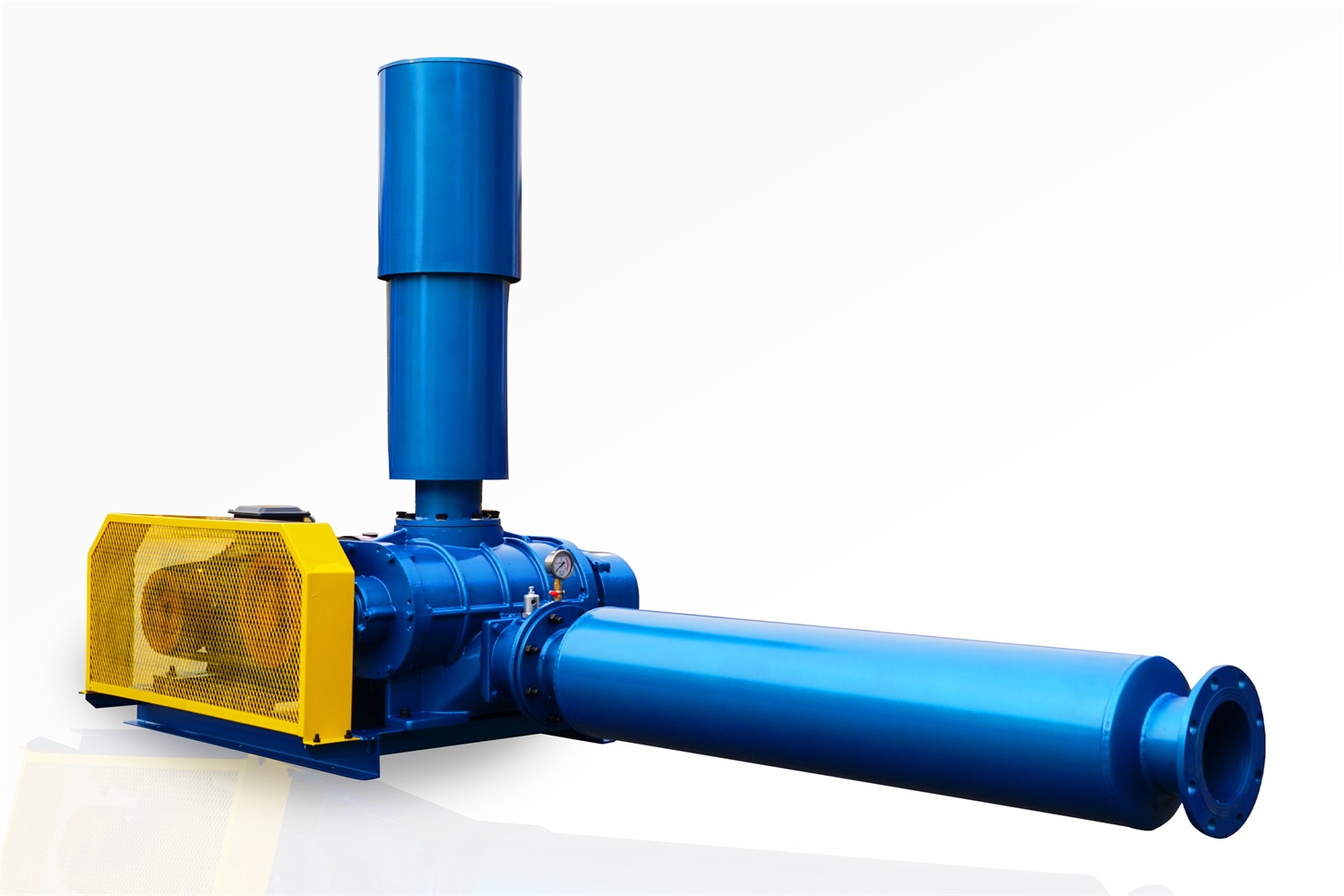

水产增氧机的管道和维护方法:水产增氧机的管道上应设置排空阀,以防止增氧机皮带负荷启动,增氧机应在空载启动后逐渐关闭排空阀。带负荷运转,停机后,要打开排空阀,确认增氧机没有负荷,然后关闭增氧机。增氧机的管道不能漏气,要在适当的位置安装支架,连接牢固。如果多台增氧机同时进行,则需要在各分管安装闸阀(其中一台增氧机维修时可以切断该管道)。管道材料要能承受排气温度和压力。(可使用钢管)管道内部要干净,没有异物,不要让杂物进入。在增氧机管道上安装单向阀门,防止增氧机反向产生的回流高压气体进入增氧机,这可能会导致增氧机损坏。

Pipeline and maintenance method of aquatic aerator: the pipeline of aquatic aerator shall be provided with an emptying valve to prevent the belt load start of the aerator. The aerator shall gradually close the emptying valve after no-load start. Operate with load. After shutdown, first open the emptying valve, confirm that the aerator has no load, and then close the aerator. The pipeline of the aerator shall be free of air leakage, and the support shall be installed at an appropriate position and firmly connected. If multiple aerators are operated at the same time, it is necessary to install gate valves in each branch pipe (the pipeline can be cut off when one aerator is repaired). The pipe material shall be able to withstand the exhaust temperature and pressure. (steel pipe can be used) the inside of the pipe shall be clean and free of foreign matters, and sundries shall not be allowed to enter. Install a one-way valve on the pipeline of the aerator to prevent the return high-pressure gas generated in the reverse direction of the aerator from entering the aerator, which may cause damage to the aerator.

水产增氧机效率高,能耗低。增氧机转子采用特殊设计,啮合曲线用高复合线密封,泄漏少,容积效率进一步提高。水产增氧机运行平稳,无振动。采用叶轮加工专用加工,转子啮合间隔均匀,形成平衡状态,在此基础上,增氧机转子经过更精的平衡试验,运行几乎不振动。水产增氧机的转子在一定转速下,在允许升压的设计范围内变化时,流量几乎不变,也就是说,改变转速可以改变气流。排气量的大小决定机器大小和转速,但与压力大小无关,通过调整速度的方法可以减少外部排气量,经济效益非常明显。

The aquatic aerator has high efficiency and low energy consumption. The rotor of the aerator adopts special design, and the meshing curve is sealed with high composite wire, which has less leakage and further improves the volumetric efficiency. The aquatic aerator operates stably without vibration. The impeller is specially processed, and the rotor meshing interval is uniform to form a balanced state. On this basis, the rotor of the aerator passes a more precise balance test and runs almost without vibration. When the rotor of aquatic aerator changes within the design range of allowable pressure rise at a certain speed, the flow is almost unchanged, that is, changing the speed can change the air flow. The size of the exhaust volume determines the size and speed of the machine, but it has nothing to do with the pressure. The external exhaust volume can be reduced by adjusting the speed, and the economic benefit is very obvious.