提高气动输送系统管道的耐磨性的小技巧

Tips for improving the wear resistance of pneumatic conveying system pipes

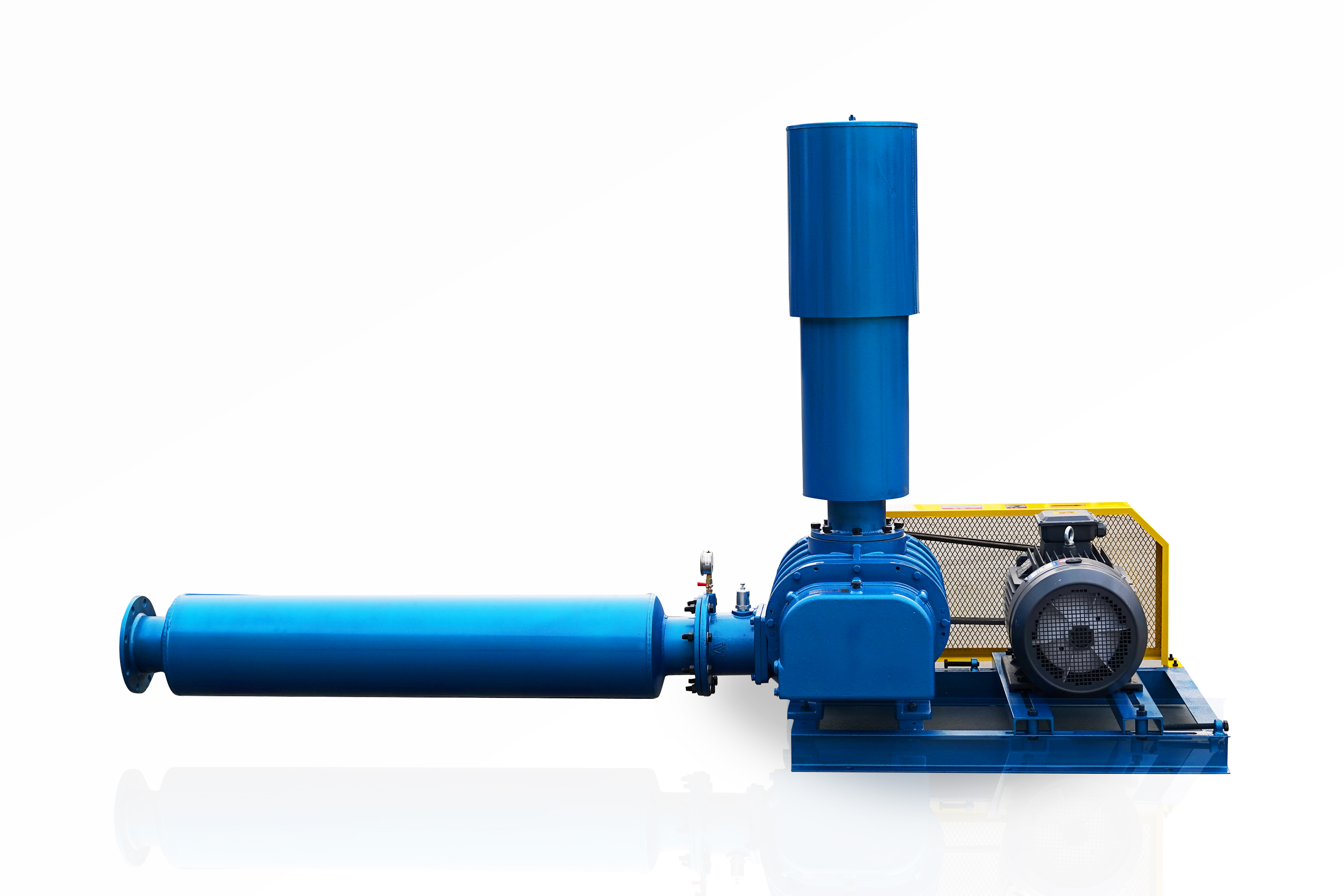

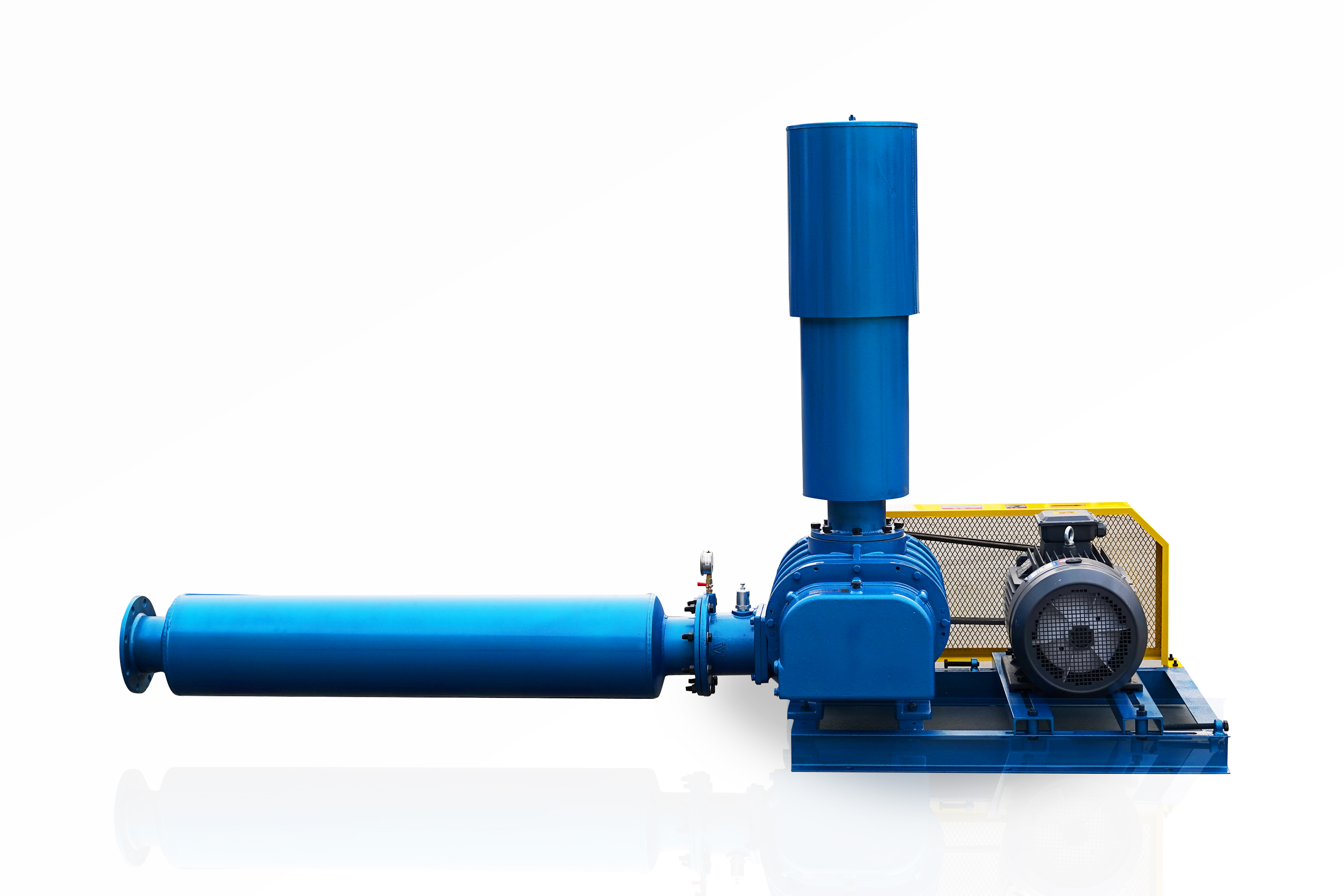

有人说,气力输送系统是完善的,可以解决粉尘污染问题,可以有效地完成生产运输工作。它是输送设备中理想的粉末输送系统,但黄金并不。无论是设备还是人,它都不会真正。

Some people say that the pneumatic conveying system is perfect, which can solve the problem of dust pollution and effectively complete the production and transportation work. It is an ideal powder conveying system in conveying equipment, but gold is not perfect. Whether it is equipment or people, it will not be really perfect.

在气动输送系统中输送散装物料的过程中,容易出现故障的是气动输送管道的磨损。有时,设备的严重性会导致整个设备停机,因此机械师和设计人员必须不断地进行改进。改进的技术提高了气动输送系统的耐磨性,并确保了系统的平稳运行。

In the process of conveying bulk materials in pneumatic conveying system, the wear of pneumatic conveying pipeline is easy to occur. Sometimes, the severity of the equipment will lead to the shutdown of the whole equipment, so the machinist and designer must constantly improve. The improved technology improves the wear resistance of the pneumatic conveying system and ensures the smooth operation of the system.

经验表明,气动输送管的磨损与空气输送速度,所输送货物的磨损,散装物料的浓度,管道的直径以及管道中使用的物料有关。直线和拐角的磨损明显不同。对于某些输送材料,弯头的使用寿命只有几个小时,而相同材料的直截面钢管的使用寿命只有几个月。

Experience has shown that the wear of pneumatic conveying pipes is related to the air conveying speed, the wear of transported goods, the concentration of bulk materials, the diameter of the pipes and the materials used in the pipes. The wear of straight lines and corners is obviously different. For some conveying materials, the service life of elbows is only a few hours, while that of straight section steel pipes of the same material is only a few months.

由于重力的作用,水平管的磨损也不均匀,下部磨损比上部磨损更严重。因此,建议在大通过时间后,将带凸缘的厚壁管旋转90度。管道的安装过程应正确,轴线不得偏斜,并且不允许从大孔到小直径孔的过渡。

Due to the effect of gravity, the wear of the horizontal pipe is also uneven, and the wear of the lower part is more serious than that of the upper part. Therefore, it is recommended to rotate the flanged thick walled pipe 90 degrees after a large pass time. The installation process of the pipeline shall be correct, the axis shall not deviate, and the transition from large hole to small diameter hole is not allowed.

带限位连接的法兰是管道装配的佳选择。当管道磨损大时,可以使用专用管道代替倾斜管道,因为它比水平管道和直管磨损得更快。关于肘部的选择,原则是穿厚壁或简单地替换简单的肘部位置,并且使用特殊的耐磨材料通常非常好。

Flange with limit connection is a good choice for pipe assembly. When the pipe wear is large, special pipe can be used instead of inclined pipe, because it wears faster than horizontal pipe and straight pipe. As for the selection of elbows, the principle is to wear thick walls or simply replace simple elbow positions, and it is usually very good to use special wear-resistant materials.

The wonderful content of this article is provided by the knowledge of Yunnan powder conveying design scheme. There are many wonderful content on this website. You can click to enter more content: http://www.sddyfd.com/ We have special customer service to answer your questions