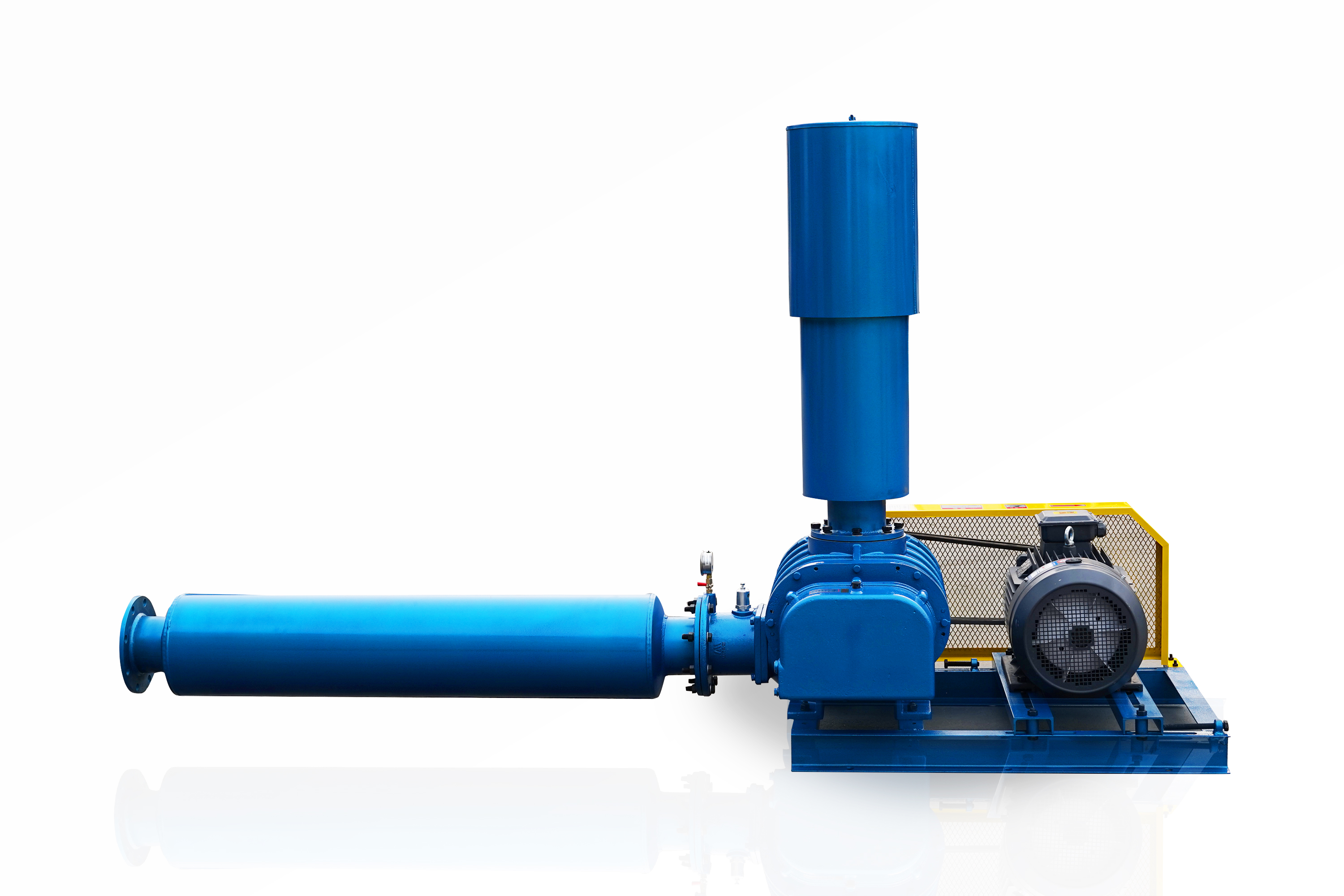

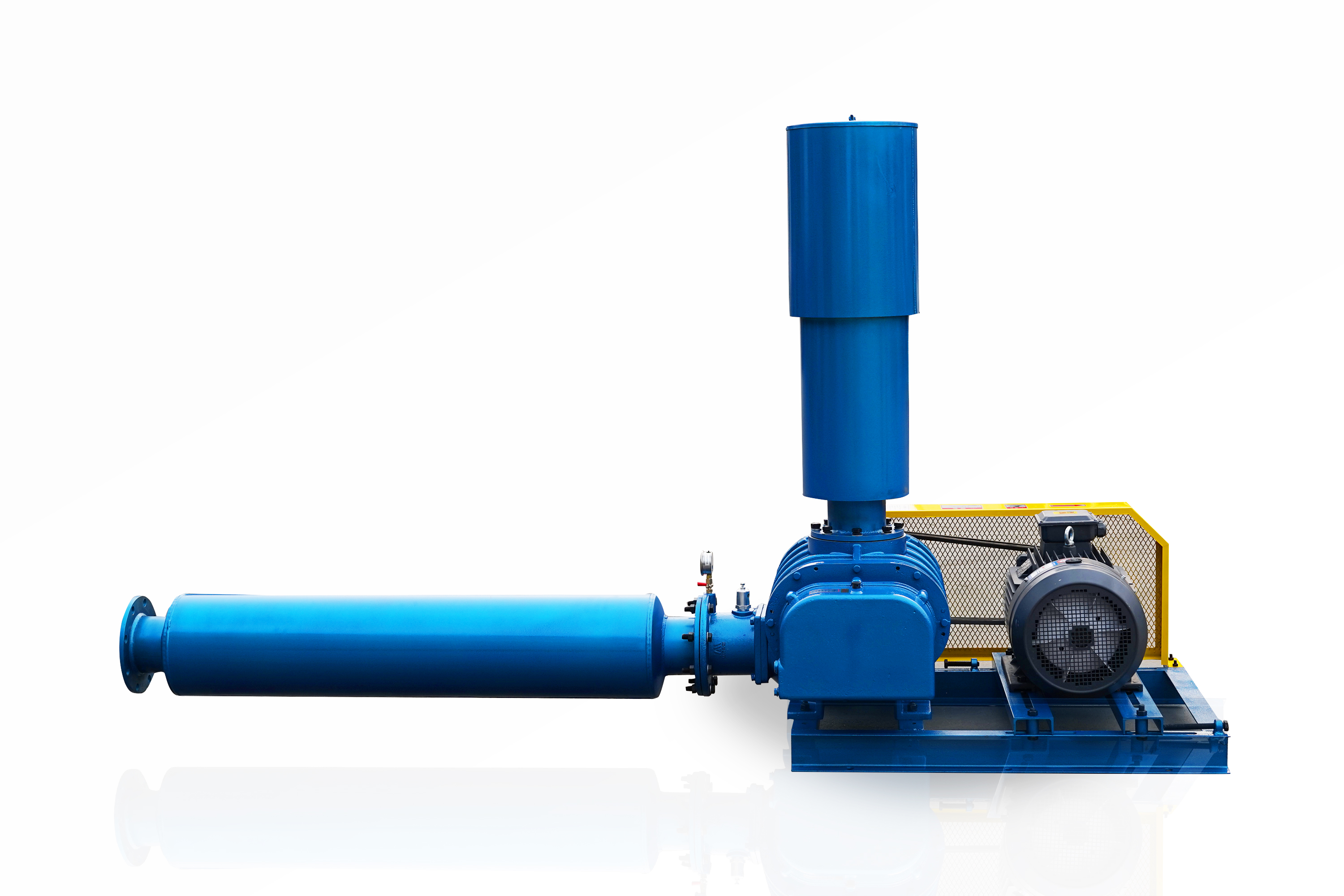

气力输送装置的结构特点有哪些?

What are the structural features of pneumatic conveying devices?

气力输送装置的结构简单,操作方便,可作水平的、垂直的或倾斜方向的输送,在输送过程中还可同时进行物料的加热、冷却、干燥和气流分级等物理操作或某些化学操作。与机械输送相比,此法能量消耗较大,颗粒易受破损,设备也易受磨蚀。含水量多、有粘附性或在高速运动时易产生静电的物料,不宜于进力输送。

The pneumatic conveying device has simple structure and convenient operation. It can be used for horizontal, vertical or inclined conveying. During the conveying process, it can also carry out physical operations such as material heating, cooling, drying and airflow classification or some chemical operations. Compared with mechanical conveying, this method consumes more energy, the particles are easy to be damaged, and the equipment is also easy to be abraded. Materials with high water content, adhesion or easy to generate static electricity during high-speed movement are not suitable for pneumatic conveying.

在水平管道中进行稀相输送时,气速应较高,使颗粒分散悬浮于气流中。气速减小到某一临界值时,颗粒将开始在管壁下部沉积。此临界气速称为沉积速度。这是稀相水平输送时气速的下限。操作气速低于此值时,管内出现沉积层,流道截面减少,在沉积层上方气流仍按沉积速度运行。

When dilute phase transportation is carried out in a horizontal pipeline, the gas velocity should be high so that particles can be dispersed and suspended in the gas flow. When the gas velocity decreases to a certain critical value, the particles will begin to deposit in the lower part of the pipe wall. This critical gas velocity is called deposition velocity. This is the lower limit of gas velocity for dilute phase horizontal transportation. When the operating gas velocity is lower than this value, a deposition layer appears in the pipe, the cross-section of the channel decreases, and the gas flow above the deposition layer still operates at the deposition velocity.

在垂直管道中作向上气力输送,气速较高时颗粒分散悬浮于气流中。在颗粒输送量恒定时,降低气速,管道中固体含量随之增高。当气速降低到某一临界值时,气流已不能使密集的颗粒均匀分散,颗粒汇合成柱塞状,出现腾涌现象(见流态化),压力降急剧升高。此临界速度称噎塞速度,这是稀相垂直向上输送时气速的下限。对于粒径均匀的颗粒,沉积速度与噎塞速度大致相等。但对粒径有一定分布的物料,沉积速度将是噎塞速度的2~6倍。

Upward pneumatic conveying is carried out in a vertical pipe. When the gas velocity is high, the particles are dispersed and suspended in the air flow. When the particle conveying capacity is constant, the solid content in the pipeline increases with the decrease of gas velocity. When the gas velocity decreases to a certain critical value, the gas flow can no longer make the dense particles disperse uniformly, and the particles converge into a plunger shape, resulting in a surge phenomenon (see fluidization) and a sharp rise in pressure drop. This critical velocity is called choking velocity, which is the lower limit of gas velocity when the dilute phase is vertically transported upward. For particles with uniform particle size, the deposition velocity is approximately equal to the choking velocity. However, for materials with certain particle size distribution, the deposition rate will be 2 ~ 6 times of choking rate.

The above is the content introduced by Guangxi pneumatic conveying scheme design. Thank you for checking the information of our company in your busy schedule. If you want to know more, you are welcome to call us for consultation! http://www.sddyfd.com/